How To Clean A 3d Printer Bed

In 3D printing communities, there'southward a lot of discussion around the best 3D printer bed cleaning methods. Whether yous're a newcomer or a veteran, we've got some tips for success.

Nosotros'll discuss various cleaning products and how to use them to clean the beds of FDM printers.

Why Clean the Print Bed?

It may seem obvious, but plastics stick amend to clean surfaces. If yous accept poor bed adhesion, your printing quality may suffer. To get the best adhesion, remove whatever buildup of filament, oil, clay, and grit.

Plus when you lot have a clean 3D printer bed, you might non need to use hacks similar gum sticks, painters tape, and hairspray to better adhesion.

Safety First

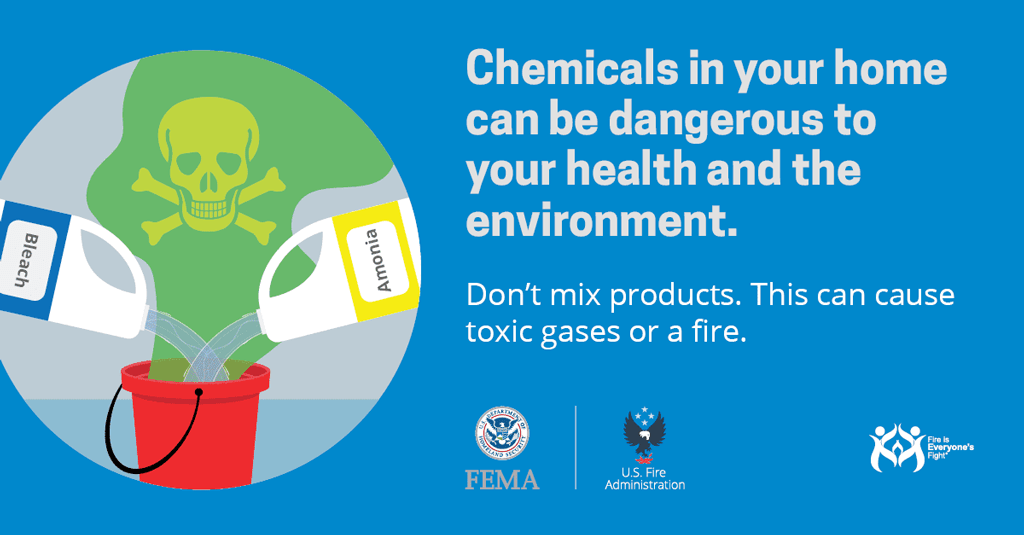

As with annihilation involving chemicals and electricity, a little common sense will go a long way to protect yourself and your belongings.

Never mix chemicals. Y'all may stop up inadvertently creating toxic and dangerous substances. Specifically, never mix acetone and isopropyl alcohol. It forms a toxic chemical, peracetic acrid, which can crusade chemic burns or worse.

Don't employ whatsoever of these products in a confined infinite, and make sure yous have adept ventilation.

Also think that acetone and all kinds of alcohol are highly flammable. All it takes to start a fire is a spark from the electronics or heated bed.

Cleaning Solutions

Simply a few cleaning products are effective and safe to use to clean the bed surface.

Isopropyl Booze (IPA)

IPA or rubbing alcohol at a 90% concentration or higher is an fantabulous cleaning solution. Annihilation above 90% volition be hard to find at a drugstore, just yous can hands notice it on Amazon.

In a pinch, you can use 70%, but go along in heed it won't remove equally much oil from the build surface, and it may contain chemicals other than just alcohol and water. When booze and h2o dry, they might go out a sparse film of other, unknown compounds on your bed.

In our experience, 70% isopropyl will practise a great job on beds that are already fairly clean. If you see fingerprints or smudges on your build plate that don't come off with 70% isopropyl, you lot may need something stronger. We've plant 90% isopropyl to exist the sweet spot between price and effectiveness.

Ethyl Booze

In theory, ethyl alcohol is also a practiced cleaning solution. Nonetheless finding it in a strong enough concentration is difficult, and in some U.S. states it's illegal to buy over the counter.

Everclear is a make of ethyl alcohol that you can purchase at a liquor store. Everclear is 190 proof, which ways information technology'south 95% alcohol.

On the whole, though, ethyl alcohol is more likely than isopropyl booze to have impurities, and information technology'southward more than expensive. For these reasons, we recommend isopropyl over ethyl alcohol.

Acetone

You might already have some acetone in your home. It'southward the master ingredient in some blast smoothen removers. Read the label, because not all nail smoothen removers contain acetone. You can find 100% acetone at hardware stores, and it's a relatively inexpensive solvent.

Acetone is extremely good at removing oil, and it evaporates very quickly. It has a very strong smell and is highly flammable. Information technology can also deliquesce some plastics like ABS and acrylic. For that reason, be very careful about what you're putting acetone on. Prevent damage to your skin, your 3D printer, floors, and furniture by fugitive contact with any other surface too the bed.

Even though it's extremely good at cleaning the build plate, we don't recommend using acetone regularly. In fact, it may damage beds that take a PEI coating.

Soap and Warm Water

Alcohol and acetone, though they can take off grease, aren't expert at removing glue sticks, which some people employ to assistance with offset layer adhesion. Dishwashing soap and water work well to remove both grease and gum stick. It's easier to use dish lather and water if yous have a removable bed because you can take it to your sink.

Recall, soap and water mixtures are conductive, so don't get whatever on the electronics on your 3D printer. It might cause a short, or, worst case, a stupor.

All in all, soapy h2o may be the best mix because information technology can remove all types of contaminants.

Glass Cleaner

Glass surface cleaners similar Windex aren't just for cleaning glass. They can act as release agents also. Windex volition remove some oil from the bed every bit well as some other water-soluble contaminants, merely it will also leave its own film behind. That might issue in less adhesion—which isn't always a bad matter.

In some cases—like when press with PETG onto a PEI-coated printing surface—your prints may stick then well that they tin can pull up the PEI coating when you try to remove them. If y'all're having that problem, consider using a window cleaner to clean your bed, or just spray some on to aid reduce adhesion, even if your bed is perfectly clean. Just remember to clean it again if you switch to a filament type that doesn't adhere as well, like PLA or ABS.

How to Clean Your 3D Print Bed

The steps for cleaning the bed of a 3D printer are largely the same, whether you lot have a drinking glass bed (similar the Anycubic Kobra Max), a metal bed (similar the Voxelab Aquila), a magnetic bed (like the Anycubic Vyper), or a PEI-coated bed (like some Ender three printers).

At that place's actually just one exception. You lot shouldn't use acetone to clean PEI sheets because it might damage the PEI sheet over fourth dimension. With that in mind, follow these steps for cleaning beds of unlike materials.

These are the steps for cleaning with isopropyl alcohol, ethyl alcohol, acetone, or Windex:

- Using a scraper, remove whatsoever leftover filament residue or adhesive tape from the glass plate, metal bed, or PEI canvas.

- Brand certain the bed is at room temperature. Otherwise, the cleaning fluid will evaporate. You want to give it time to soak the oil off.

- Don't impact the bed directly with your hands, lest y'all recontaminate it. Pretend you're a surgeon.

- Always add together your cleaning solution to a clean paper towel or textile and avoid spraying it directly on the bed considering the mist might go into your electronics. Put enough cleaning solution on the newspaper towel then yous're able to wipe down the whole bed before it starts evaporating.

- Methodically make clean the entire bed, applying pressure evenly throughout the cleaning process.

- Optionally, introduce a 2nd newspaper towel or clean cloth to dry out the bed. Drying can remove even more surface contaminants and oil, and information technology tin dust off any remaining dirt or pieces of the first paper towel. The kickoff pass is dissolving the contaminants. The 2d pass is removing those contaminants. If your bed is relatively make clean, y'all tin can skip the second pass. If you're having adhesion issues, definitely dry the bed.

If yous see any remaining smudges, fingerprints, etc., repeat the steps above until they're gone.

With Soap and Water

When using soap and water to clean the bed, follow these steps:

- First, wash your hands thoroughly.

- Wash the bed like you lot would a dish, but don't utilise anything abrasive. A soft sponge or cloth will work. You could only utilize your hands, but you'll get off more than grease if you utilize a sponge, cloth, or paper towel.

- Add some force per unit area while you're soaping it up to help dislodge the oil.

- Then rinse all the soap off. Don't leave whatever behind. You don't want any soap left on the bed at all.

- Lastly, dry the bed thoroughly with a new, clean material.

Keeping Your Bed Clean

The best way to take a clean bed is to not get information technology dingy in the first place. Avert touching the bed at all, if possible. Thoroughly clean your hands if y'all do need to handle the bed. Better yet, clothing clean gloves. Nitrile or latex gloves work great.

Once you've cleaned the bed, only touch it on the sides. Keeping your bed clean ways future prints are more likely to be successful.

*Special cheers to FormerLurker for his 3D printing expertise.

Do non share my Personal Information.

Source: https://www.online-tech-tips.com/computer-tips/how-to-clean-a-3d-printer-bed/

0 Response to "How To Clean A 3d Printer Bed"

Post a Comment